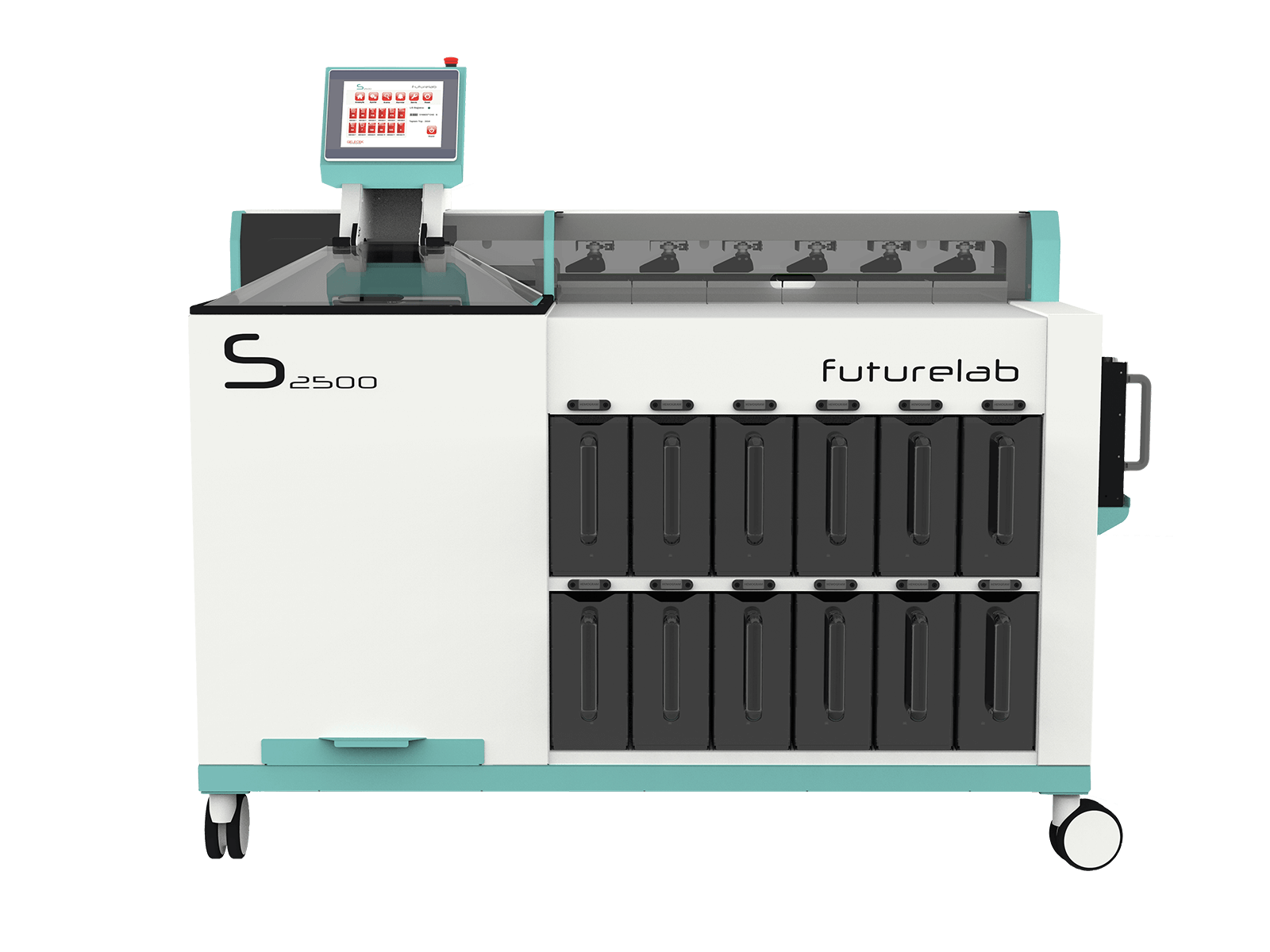

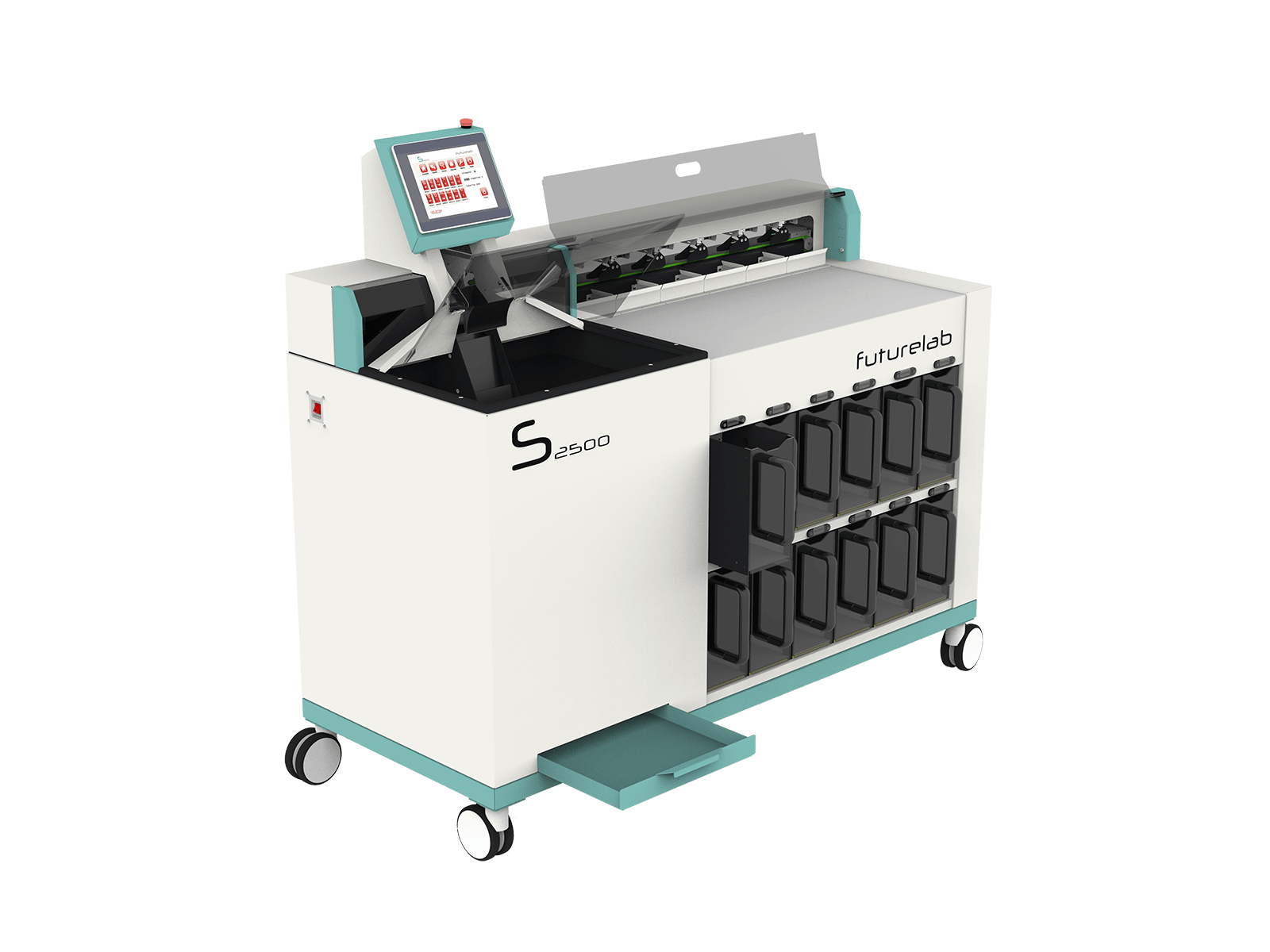

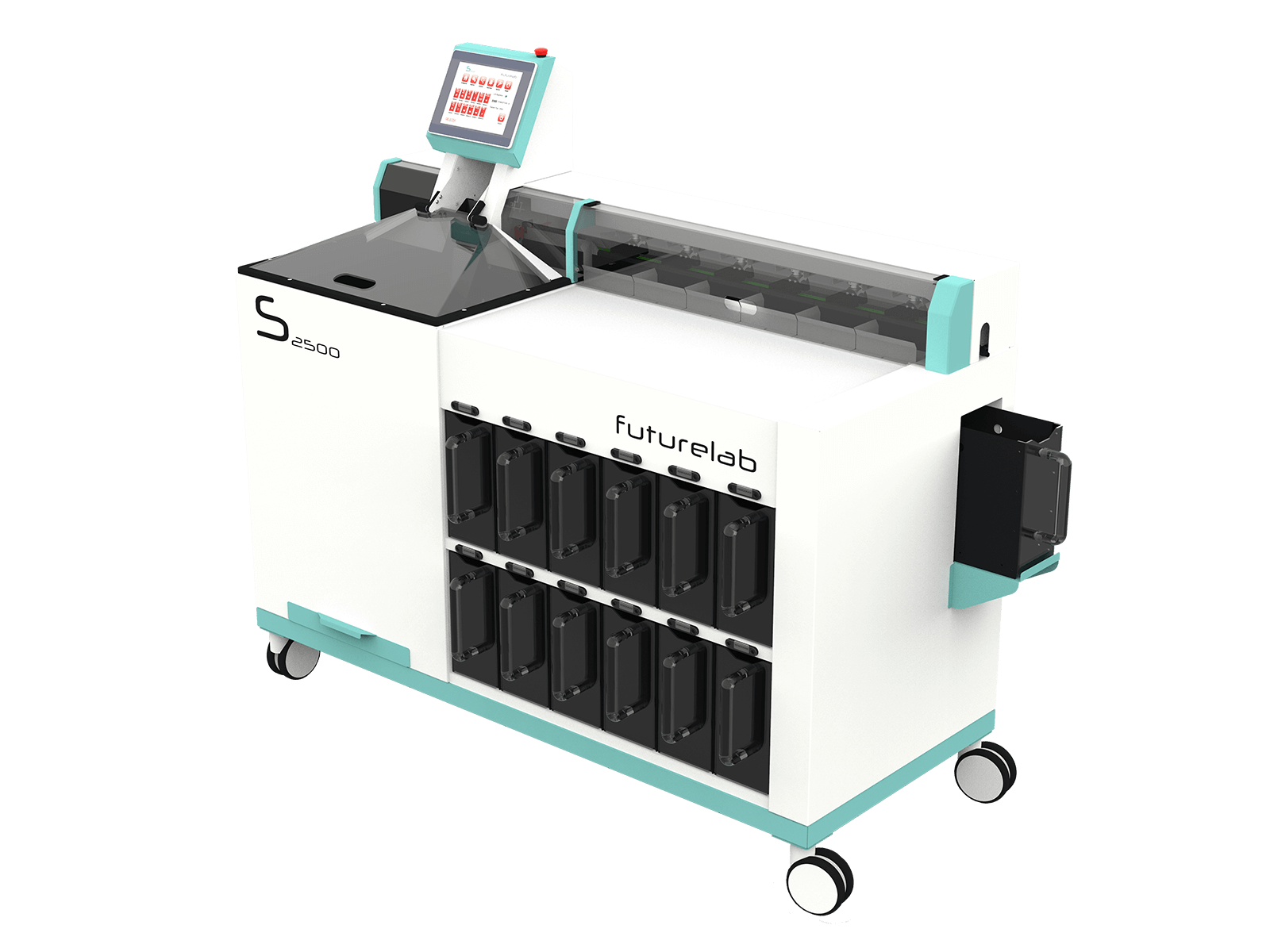

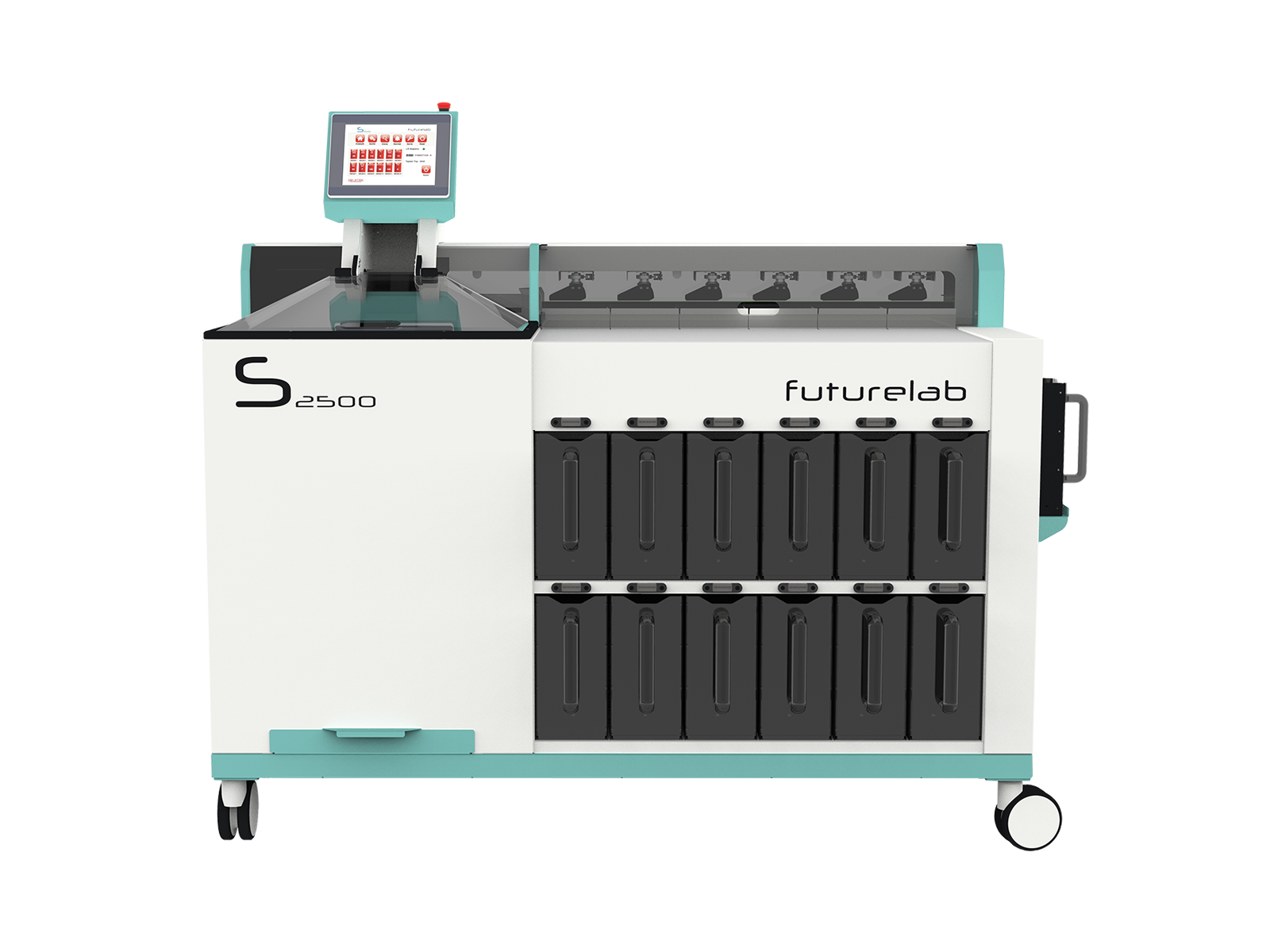

S2500

The Futurelab S2500 Tube Sorter is an automated system to load and sort blood collection tubes by the LIS or HIS order. it improves the workflow in clinical laboratories, particularly in the preanalytical phase in the entrance area and it allows laboratory staff to make their time more efficient and concentrate on their main tasks.

Technicial Specifications

The Futurelab S2500 Tube Sorter is an automated system to load and sort blood collection tubes by the LIS or HIS order. it improves the workflow in clinical laboratories, particularly in the preanalytical phase in the entrance area and it allows laboratory staff to make their time more efficient and concentrate on their main tasks.| Available tube | Diameter: 8 to 19 mm Length: 72 to 120 mm Stopper: rubber, film, plast |

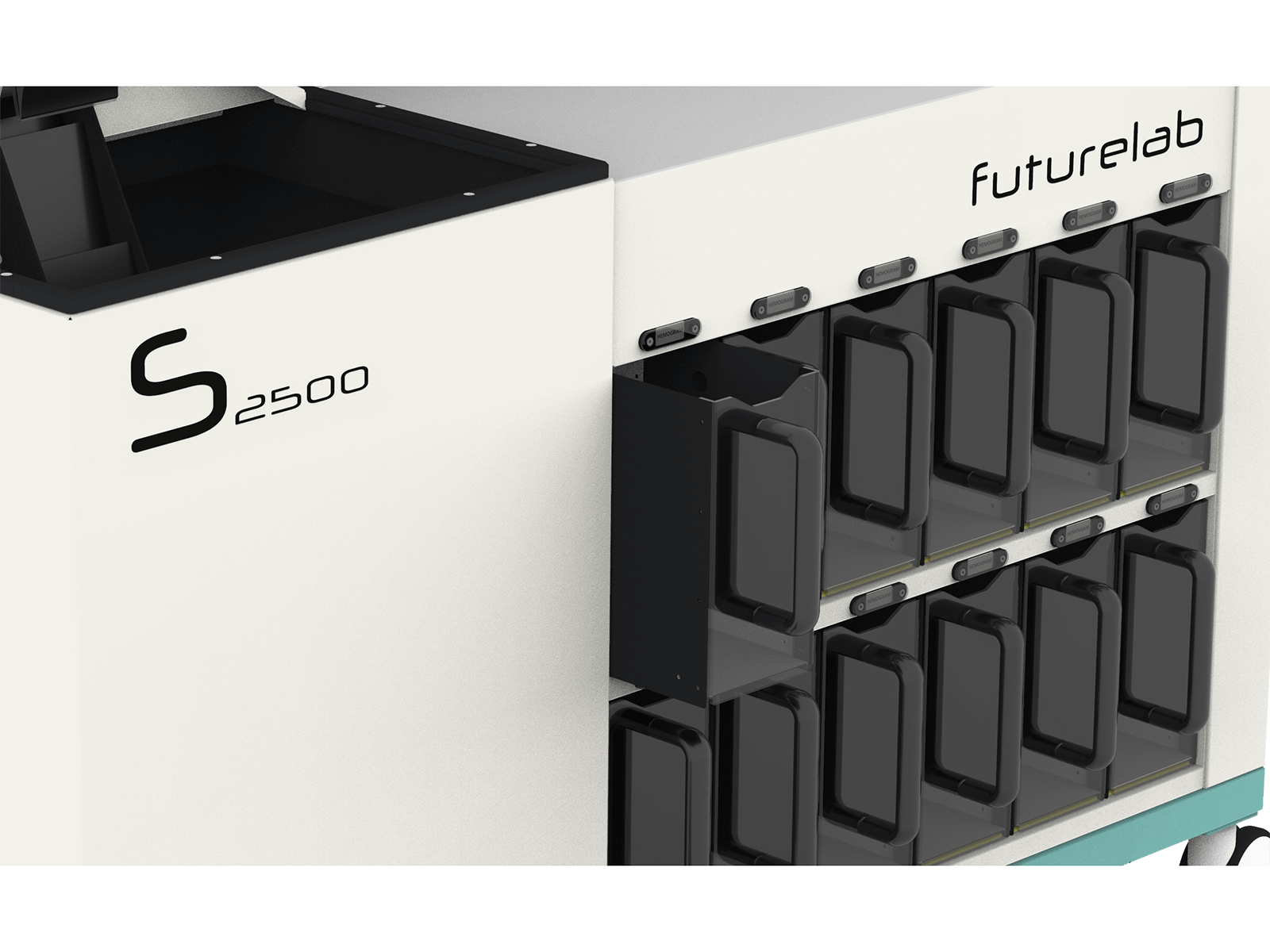

| Number of sorting targets | 12 + 1 |

| Target bin capacity | 250 tubes per one target bin |

| Processing speed | 2500 tubes per hour |

| Tube capacity | 800 tubes + Continuous Loading |

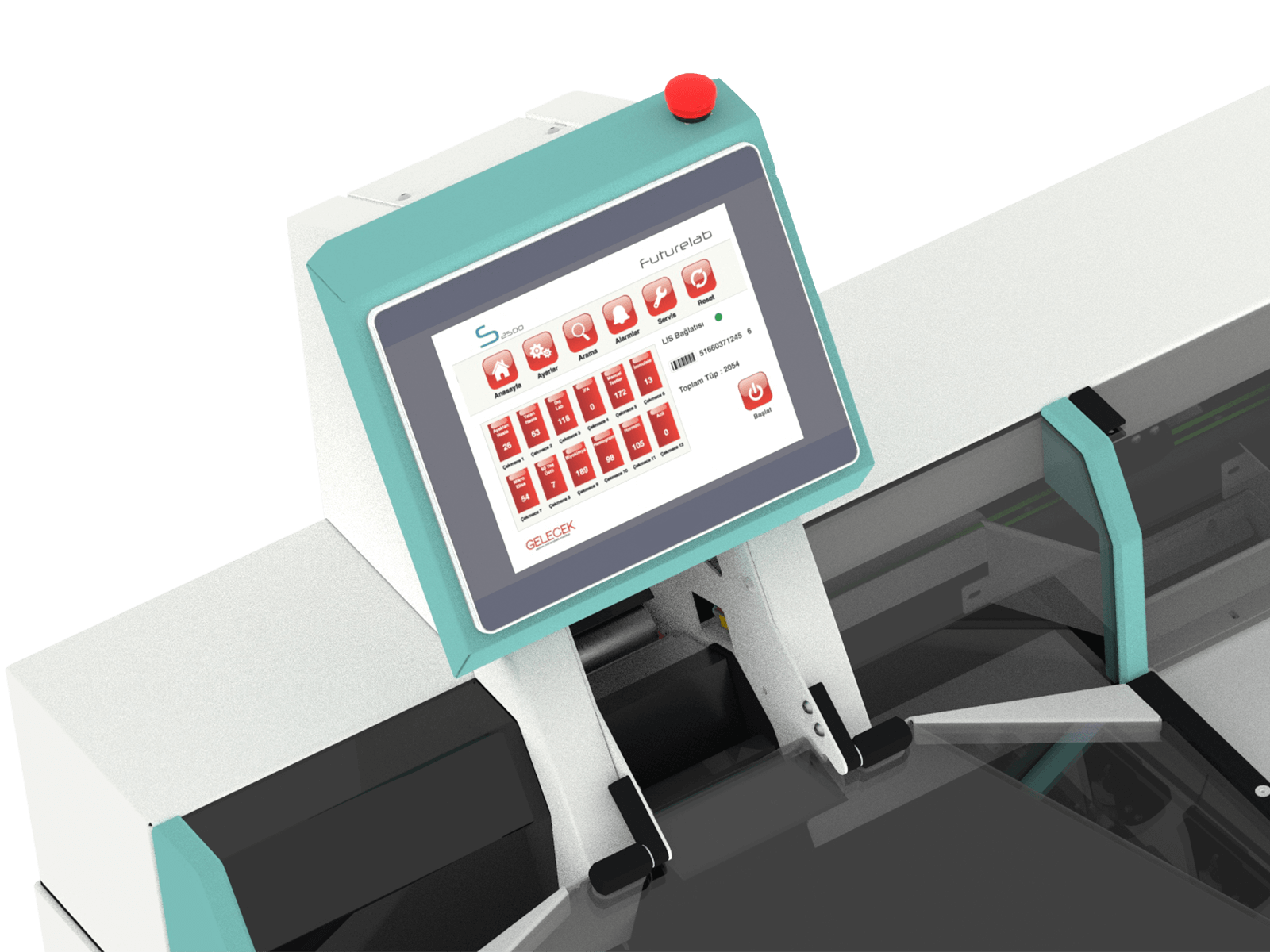

| Operating unit | Touch-screen with color display |

| Dimensions | 1859(W) x 749(D) x 1346(H) mm |

| Weight | 220 kg |

| Power source | 100-240V +- 10%, 50/60 Hz |

| Power consumption | 200VA |

| Available barcodes | Code 39, Code 93, Code 128A/B/C, 2of 5, NW7(Codabar), Jan, lnterleaved 2 of 5 ete. |

| lnterface | TCP/IP, RS232C, Ethernet, RJ45, USB Memory |

| Sorting method | Barcode, Cap-color (optional), Patient request (LIS) |

| User lnterface | Touchscreen, colored |

| Noise level | < 54 dB(A) |

| Certificates | CE |

Available Tubes

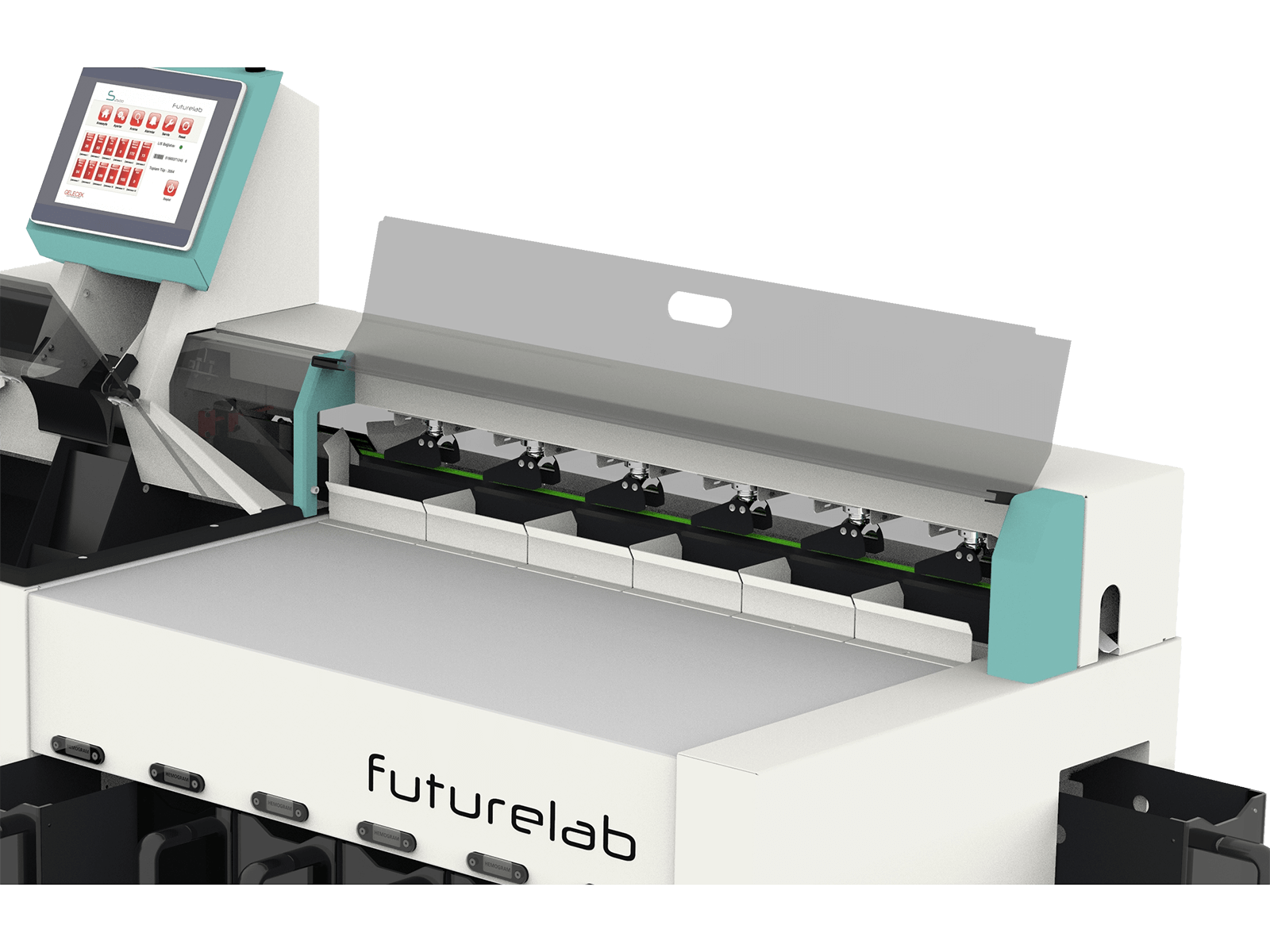

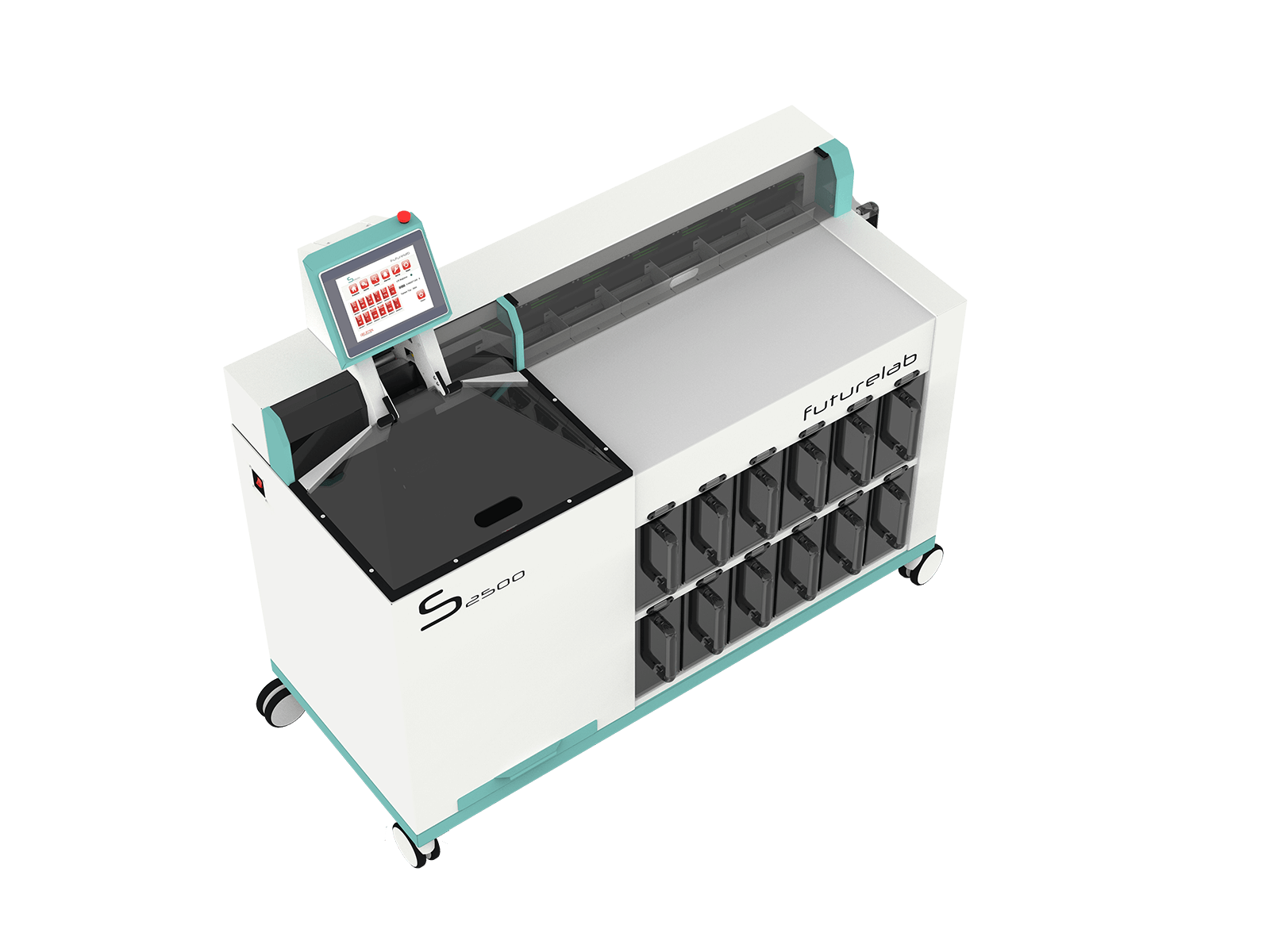

The Futurelab S2500 Tube Sorter can process and sort all types of primary tubes. Any cylindrical tube with a length of 76 - 120 mm and a diameter of 8 - 19 mm are easily handled by the machine.

High Tube Capacity

Easy and continuous sample loading in bulk, with a capacity of up to 800 tubes. Depending on the tube size each target bin holds about 250 tubes.

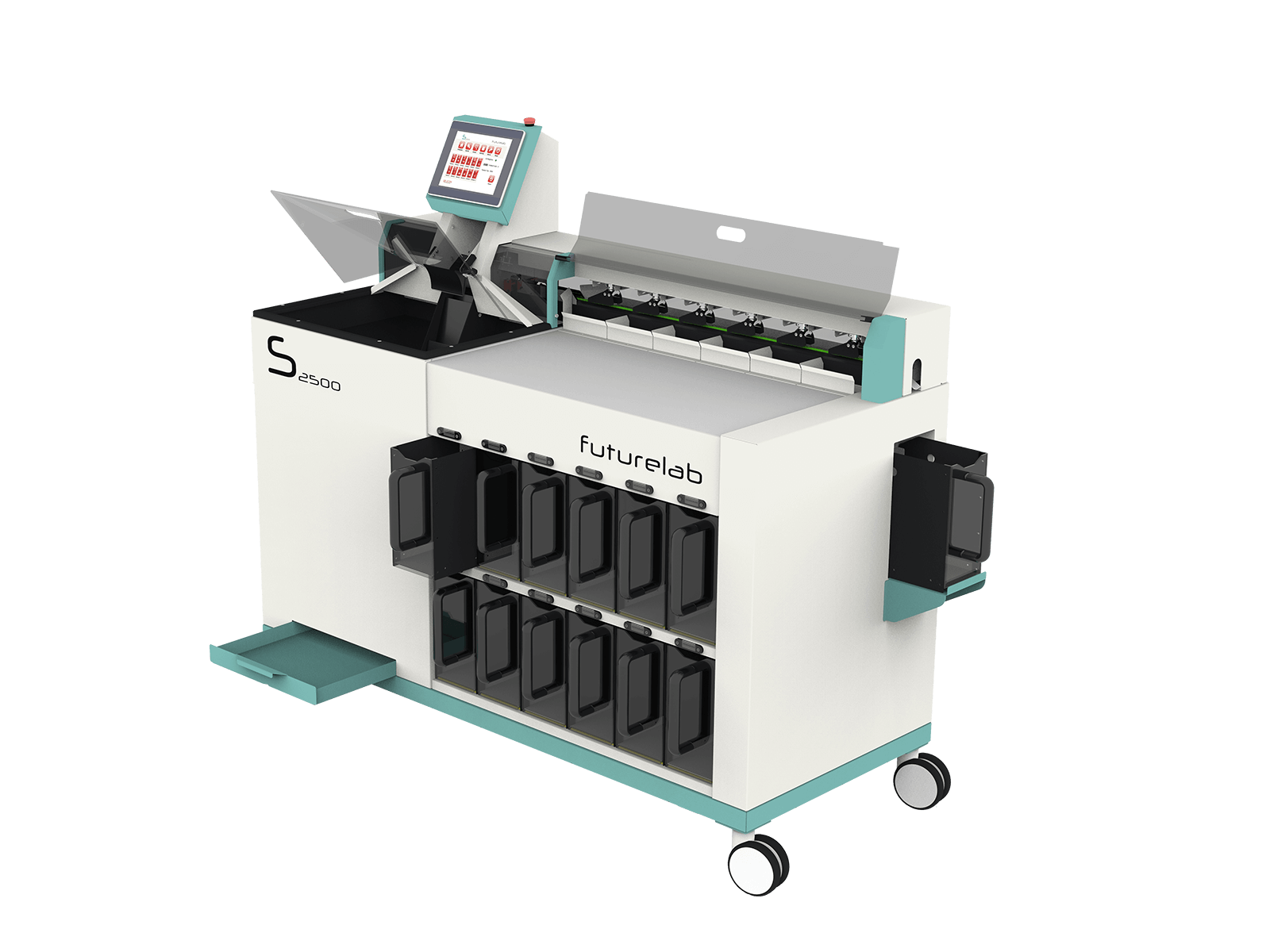

Continuous Flow

The system works on a continuous flow basis without any interruptions. The device does not need to be stopped to load tubes.

Sorting

The defined tubes are transported by a conveyor and then directed to the target drawer with the help of gates. Unidentified tubes are collected in the box at the end of the conveyor.

Sample Determination

ldentification of tubes takes place through user-defined rules based on cap color (optional) and / or barcode information or rules transmitted by the LIS.

Fast Processing

The Futurelab S2500 can handle up to 2500 tubes per hour and can easily handle blockages that occur during peak hours in the lab.